Startup Scouting – Example of a Tackled Challenge for Valeo

SIC helps us tackle technological and innovation challenges that come with the modernization and expansion of the Valeo Rakovník production plant. SIC successfully carried out a startup scouting project for us, which enabled us to find innovative startups from around the world. Together, we selected the most suitable candidates to help us enhance production efficiency, quality, and energy management across the entire plant. I strongly recommend partnering with SIC for any corporation seeking swift solutions to technological challenges and fresh opportunities for innovation.

Jakub Drahorad

Site General Manager

Valeo Autoklimatizace k.s.

Work with Valeo Autoklimatizace k.s.

Who are we?

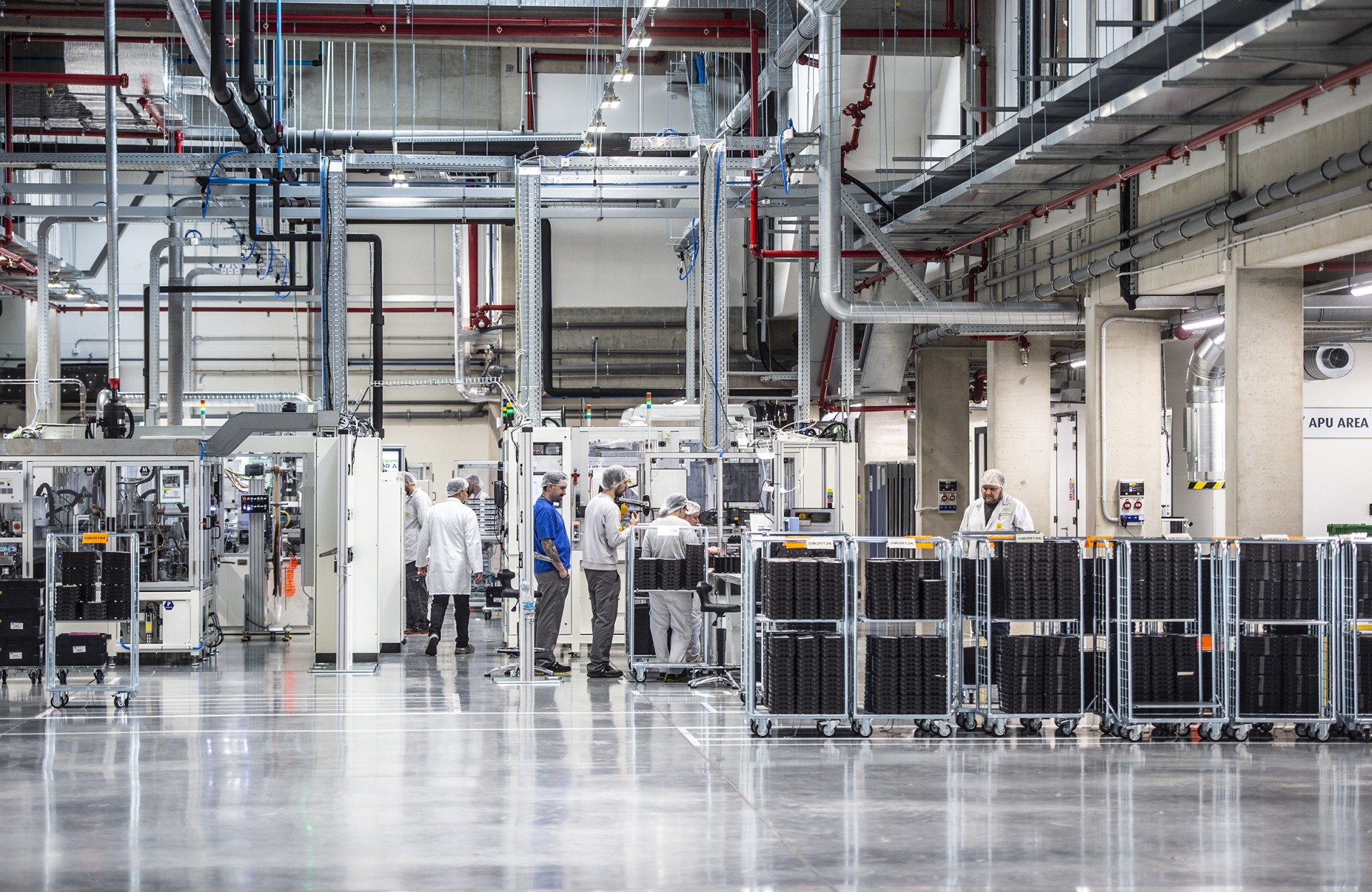

We’re a proud member of the global Valeo Group, whose groundbreaking innovations have propelled it from the automotive industry to become a frontrunner in the world of mobility. Our focus lies in harnessing innovation capacities to develop cutting-edge technologies that advance our vision of making clean and safe mobility an everyday reality for drivers and passengers worldwide. Located near Prague, we at Valeo Autoklimatizace produce essential components for assistance and autonomous systems used by the world’s leading automotive manufacturers every 10 seconds. A startup like yours has the potential to help us improve the daily comfort and safety of drivers, whilst furthering the sustainability of car travel.

What are the benefits of working with us?

Accelerate your technological development

- Refine your solution with our technology experts.

- Test it in a real automotive production line environment.

- Accelerate your technological development using our cutting-edge manufacturing technologies.

Gain new business opportunities

- Discover how your solution impacts the business.

- Bring your solution to modern manufacturing facilities in the Czech Republic.

- Get a valuable reference from us.

- Gain access to more than 180 production sites in 29 countries worldwide within the global Valeo Group.

What are we looking for in your startup?

- You have your own product that is ready to be deployed in real-life operation.

- You have successfully completed at least one project with a larger company where you have deployed your product.

Previously opened opportunities

Specific opportunities for you

We are looking for a startup that will help us solve one or more of the challenges we face in our modern Valeo plant in Rakovník.

1) Predictive maintenance of production lines – Apply by 25 August 2024

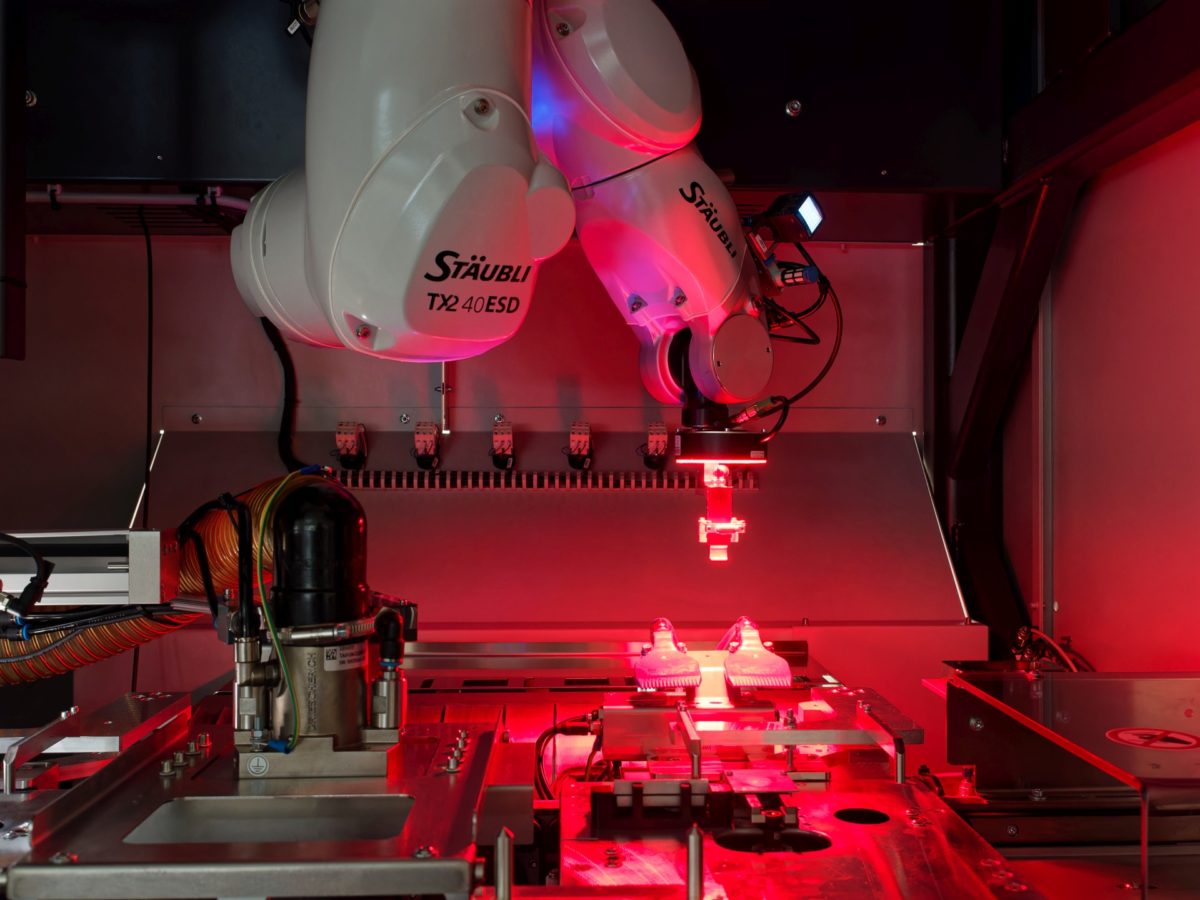

A) Rain Light Tunnel (RLT) production line

We need to coordinate a 6-axis robot and a high-speed conveyor belt in the production of ultrasonic sensors:

- The 6-axis robot fits components that are transported on a magnetic conveyor belt. We have to recalibrate the robot about every month or two because deviations in the order of tenths of a millimetre occur between the robot and the conveyor belt.

- We’re not sure whether the problem occurs directly on the conveyor system itself, or during the previous operation where the robot inserts the HT module (flex cable) into the PCB connector, which is then inserted into the housing that is transported on the conveyor belt.

Production of parking sensors and front cameras (photo: Valeo)

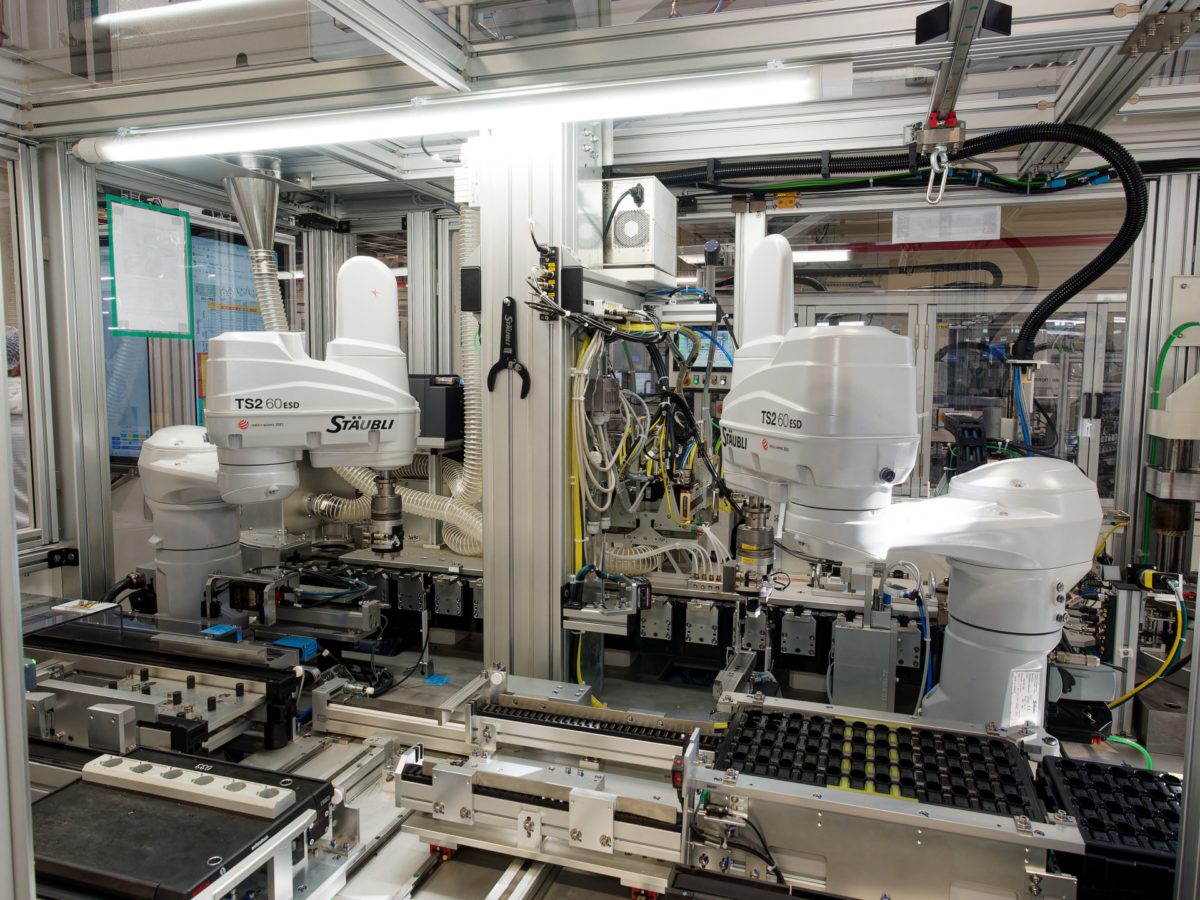

B) Surface-Mount Technology (SMT) production line

We need to find a way to predict failures in the automated fitting of electronic components on printed circuit boards (PCBs).

Underfill station

- Quality issues often arise when dispensing underfill onto mounted chips and PCBs.

- The root cause is a poorly cleaned dispenser whose valve gets clogged up with paste. We usually clean the dispenser manually or use an ultrasonic cleaner.

- We need sensor data to predict when the dispenser gets clogged.

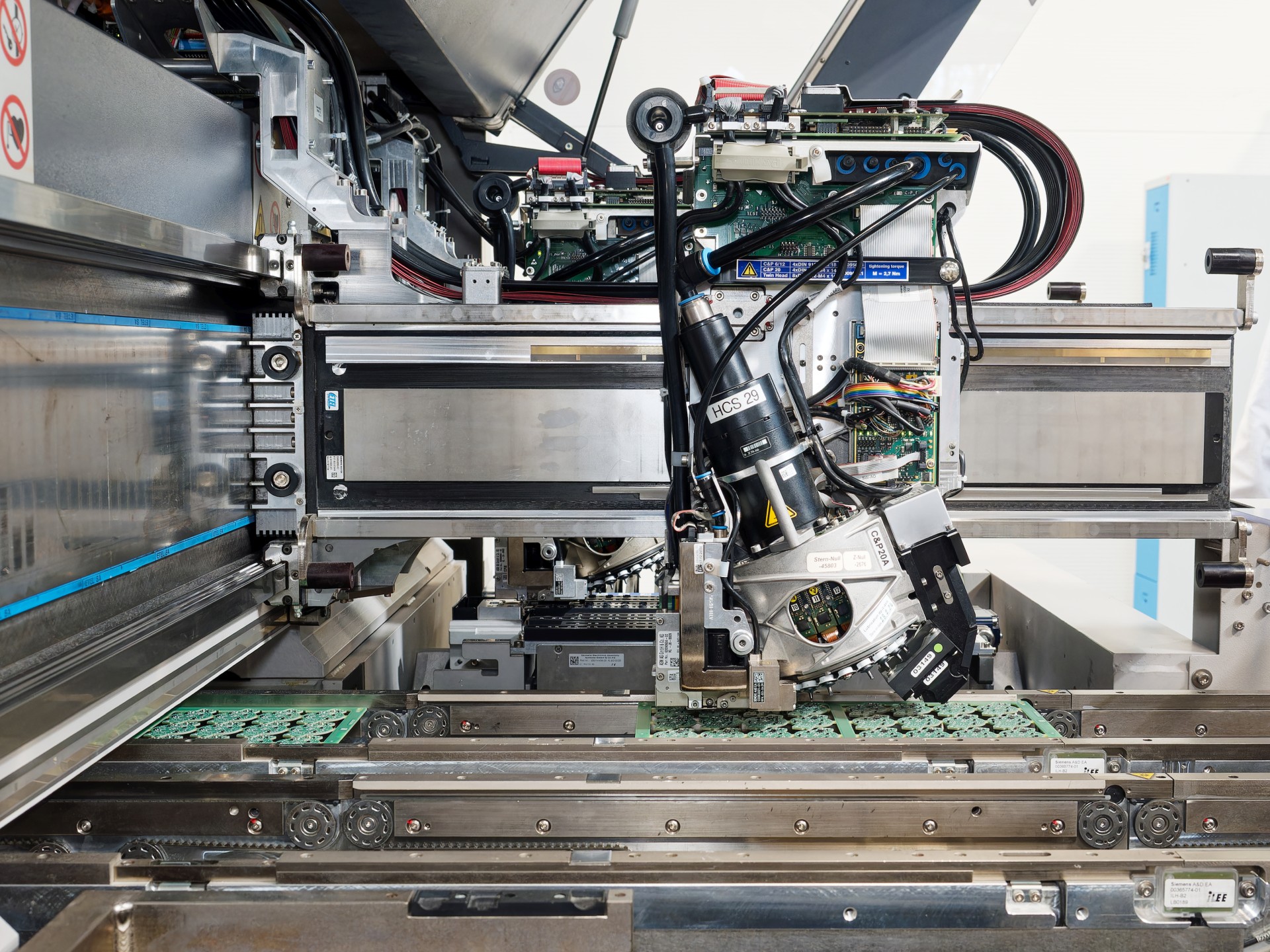

Pick-and-Place (P&P) station

- When a high-speed, pick-and-place robot places components onto PCBs, the components often fall from its gripping arm.

- Problem 1: The robot is unable to pick individual components from the reels because there are deviations in their spacing. We need to correct the robot’s movements so that it adapts to the component spacing deviations on the reels.

- Problem 2: Reels may be incorrectly connected to the machine feeder where the robot is picking the components. Connection to the feeder is done manually and we need to find a way to automate checks to ensure it’s done correctly.

SMT production line at Valeo Rakovník (photo: Valeo)

2) Controlling the energy consumption of a production plant – Apply by 15 September 2024

Our production halls have an annual consumption of 9 GWh with a reserved capacity of 12 MW. Our aim is to reduce the energy intensity of the production and optimise electricity consumption throughout the plant.

We’re looking for a startup to help us implement a smart system that will effectively manage and predict our energy consumption and help us integrate new renewable energy sources.

- What we need to do specifically:

- Measure the energy consumption at both the production line level and at the level of individual machines.

- Evaluate our data from manufacturing machines and other relevant factors, and use AI and advanced data analytics to predict where we can save energy.

- Integrate the prediction and management of energy consumption into our production planning (Advance Production Planning platforms).

- Deal with consumption peak balancing/cutting at the level of total energy consumption as well as load management for individual phases.

- Integrate photovoltaic systems (5,000+ m²) into the plant’s energy management, implement new Smart Grid solutions and acquire additional carbon-free energy sources for production.

Valeo Rakovník production plant (photo: Valeo)